In the dynamic world of industrial automation, robotic arms rarely move in a single plane. They twist, bend, and rotate simultaneously. For the high-flexible cables powering these machines, this creates a complex stress environment known as "3D Mechanical Stress."

Standard testing machines often test bending or torsion separately. However, to truly guarantee that a cable won't fail inside a multi-axis robot, you need to simulate both forces at the same time.

Today, we introduce the solution for this exact challenge: The TH-5814 Cable 3D Torsion Testing Machine by Suzhou Tophung.

The TH-5814 series is engineered with a unique composite torsion-bending combination structure. Unlike traditional testers, this machine fixes the upper end of the cable sample to a bending fixture while the lower end is secured to a rotating platform.

This setup allows for a synchronous test, subjecting the metal wire to repeated torsion and bending actions simultaneously. This is the only way to accurately detect plastic deformation defects that occur under complex, real-world usage.

1. Compliant with Global Standards For manufacturers exporting globally, compliance is key. The TH-5814 is suitable for high flexible cable testing requirements according to major international standards, including TUV 2TFG 2577, UL RP5770, VDE-PB-0022, IEC60227-2, and CRIA 0003.

2. High Efficiency & Throughput Time is money in the laboratory. The TH-5814 features 3 test stations, allowing you to test multiple samples at once.

Test Speed: Adjustable from 0 to 60 times/min.

Torsion Angle: 0° to ±720°.

Bending Angle: 0° to ±120°.

Flexibility: The torsion and bending starting angles can be synchronized or set independently via the PLC touch screen.

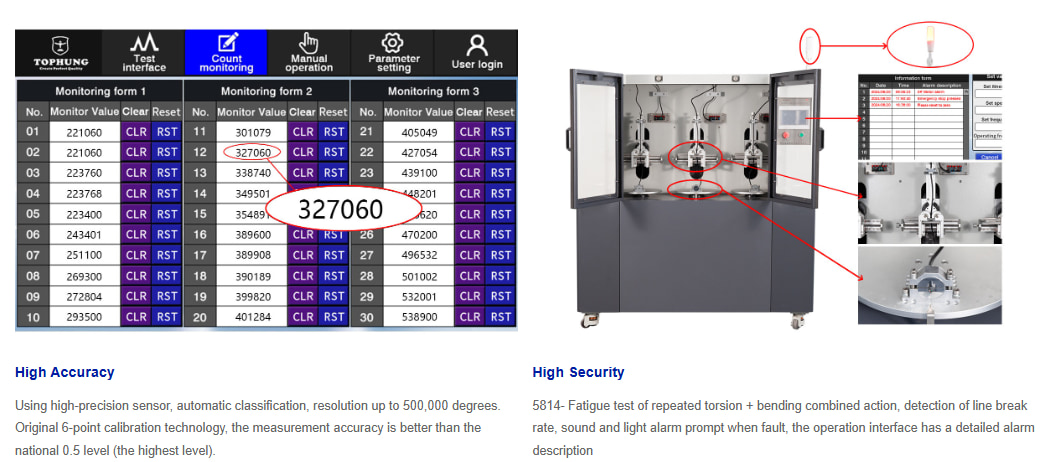

3. Intelligent Failure Detection Testing until destruction is useless if you miss the exact moment of failure. The TH-5814 can equipped with 30 pairs of monitoring interfaces.

Real-time Monitoring: The device can be extended to multi-channel resistance monitors to track connectivity online.

Instant Alarm: If a line break occurs, the system triggers a sound and light alarm, and the interface displays a detailed fault description.

4. Precision Accuracy Data reliability is ensured by high-precision sensors and original 6-point calibration technology. The measurement accuracy is better than the national 0.5 level (the highest level), with a resolution of up to 1/500,000.

Model: TH-5814 Series

Specimen Diameter: Ф1.0mm ~ Ф16mm

Distance (Fixed point to Torsion point): 100~300mm

Safety: Integrated safety protection box with sound/light alarms

Power Supply: 220V, 50/60Hz

With over 12 years of focus on the test equipment field and 6 years of exporting experience, Suzhou Tophung understands the needs of the global market. We offer a 1-year warranty, life-long maintenance, and promise a reply within 48 hours for any service issues.

Ready to upgrade your lab for the robotic age? The TH-5814 has a lead time of just 25 working days. Contact us today to ensure your cables can withstand the twist and turns of the future.